Aluminum is a substance of chemistry or chemical substance that has the atomic number 13 with the symbol of Al. Its density is lower than other common metals if compared with steel then it would be around one-third of that. It has a great attraction towards oxygen, when exposed to air it forms a protective layer of oxide on the surface.

Although it rarely occurs in its purest state in nature, aluminum is one of the most common mineral in the crust of the earth. Bauxite, a material that is mined all over the world and used to make aluminum, is the source of the metal, but it took until 1888 for a commercially to develop a practical aluminum production technology.

After being mined, crushed bauxite is misted with water. The leftover bauxite is kiln-dried, combined with a mixture of soda ash and lime, and any residual clay and silica will be eliminated as waste products. Before being baked in an oven for calcining, the final mixture passes through a number of different manufacturing processes. Alumina is a powdery substance created chemically when aluminum and oxygen mix.

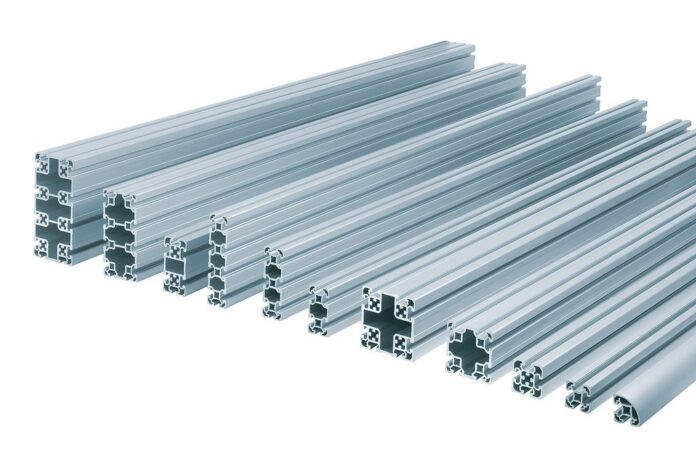

Aluminum profile is the different type of products formed from aluminum alloys that are changed into differently shaped objects through the process of extrusion. Its combination of physical characteristics depends on the process of the aluminum profile.

Whereas, aluminum extrusion is a process that is used to create the objects of a definite cross-sectional profile into the desired cross-section by pushing material.

Products including panels, engine blocks, roof rails, transmission housings, and the chassis of cars, trucks, and boats are all made utilizing aluminum extrusions. Other components of cars, like their bodies, are also made of aluminum.

Some common profiles of aluminum extrusion include square, duct, corners, and round, U, Z, and T. These profiles are readily available and always on hands, as are the dies needed to create them, at all extrusion manufacturers. They are available in a wide variety of size and lengths.

Aluminum alloys for aluminum profiles are raw materials, which are then changed into shaped products. The distinctive combination of physical characteristics present in aluminum is essentially the result of this process. Aluminum extrusions are used in many different industries because of the strength and durability of this metal.

Here are several benefits as well of aluminum profile and extrusion:

-

WEIGHT-

Comparing aluminum to metals like steel, copper, or brass, it weighs around one-third less.Because of this, aluminum extrusions are more convenient to handle, more affordable to ship, and a desirable material for use in transportation and other moving-parts-intensive applications.

2. STRENGTH-

By including various thicknesses of walls and structural strengthening in the profile design, the strength may be targeted where it is actually required due to the structure of the extrusion process. Aluminum extrusions can be manufactured as strong as required for the majority of applications. Extrusions are especially useful for cold-weather applications because aluminum gets stronger as the temperature drops.

3. MATERIAL-

Aluminum extrusions are perfect for applications like aircraft, truck trailers, and bridges where load carrying is a crucial performance component due to their unique mix of high strength and low weight.

4. STRONG-

Aluminum extruded components are used in vehicle crash management systems because of their strength and flexibility. Aluminum may flex under stresses or rebound from an impact.

5. CORROSION-

Because aluminum does not rust and has a protective oxide layer on its surface, aluminum extrusions have high corrosion resistance. With the help of other finishing techniques including anodizing, this protection can be further improved.

6. THERMAL CONDUCTOR-

Aluminum extrusion is perfect for applications needing heat exchangers or heat dissipation since it conducts heat and cold better than other popular metals based on weight and total cost. The adaptability of extruded aluminum enables designers to maximize heat dissipation in housings and other components.

7. NON-SPARKLING

Aluminum extrusions are excellent choices for applications involving explosive materials or taking place in extremely combustible situations since they are non-sparking.

8. ELECTRICAL CONDUCTOR-

Extruded aluminum is a more affordable option for electrical connectors and bus bar distribution components since it is twice as conductive as copper pound for pound.

9. NON MAGNETIC –

Extrusions made of aluminum are beneficial in high-voltage applications and electronics, both of which include magnetic fields because metal won’t develop a magnetic charge.

10. NON COMBUSTILE/TOXIC –

Aluminum does not burn and does not emit harmful vapors even at very high temperatures.

11. DELIBERATE-

Aluminum extrusion is ideal for lighting applications or for applications where it is desirable to screen areas from light, radio waves, or infrared radiation. Surface treatments can provide high reflectivity on aluminum components, making them attractive for these types of applications.

12. COHERENT-

Without the need for mechanical connecting, complex designs can be achieved in one-piece extruded aluminum parts. The finished profile is often more durable than a similar assembly and less prone to leak or become loose over time.

13. TAILORED-

Aluminum extrusions are a favored component in many product solutions even though there are numerous standard extrusion profiles available due to the ability to build a profile to satisfy certain functional, manufactureability, and, aesthetic requirements.

14. MARKET-

Aluminum extrusion tooling often has short lead times and is very inexpensive (see material comparisons), allowing for quick prototype development, product launch, and testing.

15. ASSEMBLE-

Aluminum extrusions with effective design can make fabrication and assembly much easier afterward. When fabricating extrusion-based parts and assemblies, a wide range of fabrication techniques are frequently used.

16. SUSTAINABLE-

Aluminum can be recycled endlessly without losing any of its attributes, and extrusions of aluminum are frequently. Made with a high recycled content without sacrificing their aesthetic or practical qualities. Extrusions’ inherent strengths, lightweight, and design flexibility also have a large positive impact on the environment when used.

Hence these are some of the benefits of aluminum profile and extrusion which not only help in building. Up new products with the process of extrusion but also help in the other factors related to the same